What are Ultrafiltration & Nanofiltration?

Ultra-filtration is a type of water filtration that uses a membrane to remove impurities from water. This process involves passing water through a membrane that has tiny pores that allow water molecules to pass through but block larger particles, such as bacteria, viruses, and other contaminants. Ultrafiltration is often used in water treatment plants to purify drinking water and in other industrial applications. The word "ultrafiltration" comes from the fact that this process uses a membrane with very small pores, which allows for the removal of a wide range of impurities from the water.

Ultrafiltration and nanofiltration are two different types of water filtration processes. Ultrafiltration uses a membrane with very small pores to remove impurities from water, while nanofiltration uses a membrane with even smaller pores to remove smaller impurities. The smaller pores in a nanofiltration membrane allow it to remove a wider range of impurities, including dissolved salts and other small molecules. Both ultrafiltration and nanofiltration are commonly used in water treatment plants, but they serve different purposes and are used in different stages of the water purification process.

What is the difference between these two and reverse osmosis filtration?

Reverse osmosis is a type of water filtration that uses a semi-permeable membrane to remove impurities from water. This process involves applying pressure to water on one side of the membrane, which forces the water molecules to pass through the membrane and leave the impurities behind. It is also a more expensive and complex process than the prior two, and requires more energy to operate.

Reverse Osmosis < Nanofiltration < Ultrafiltration

The smaller the pore size of the membrane, the more effective it is at removing impurities from the water. Reverse osmosis membranes have the smallest pore sizes, followed by nanofiltration membranes, and then ultrafiltration membranes. This means that a reverse osmosis system can remove a wider range of impurities than a nanofiltration system, which in turn can remove more impurities than an ultrafiltration system.

Extending the Life of Membrane Systems

In water filtration systems that use membranes, the impurities that are removed from the water are typically flushed away and discarded. The membrane itself can become clogged over time as impurities build up on its surface, which can reduce its effectiveness and efficiency. To prevent this from happening, most water filtration systems that use membranes include some type of cleaning or flushing mechanism to periodically remove the impurities that have accumulated on the membrane. This helps to maintain the performance of the system and ensure that it continues to produce clean, high-quality water.

Backwashing is a common method used to clean water filtration systems that use membranes. In a backwash cycle, water is forced through the membrane in the opposite direction to which it normally flows. This helps to loosen and remove any impurities that have accumulated on the surface of the membrane and can improve the performance of the system. Backwashing is typically performed on a regular basis, depending on the specific needs of the water filtration system.

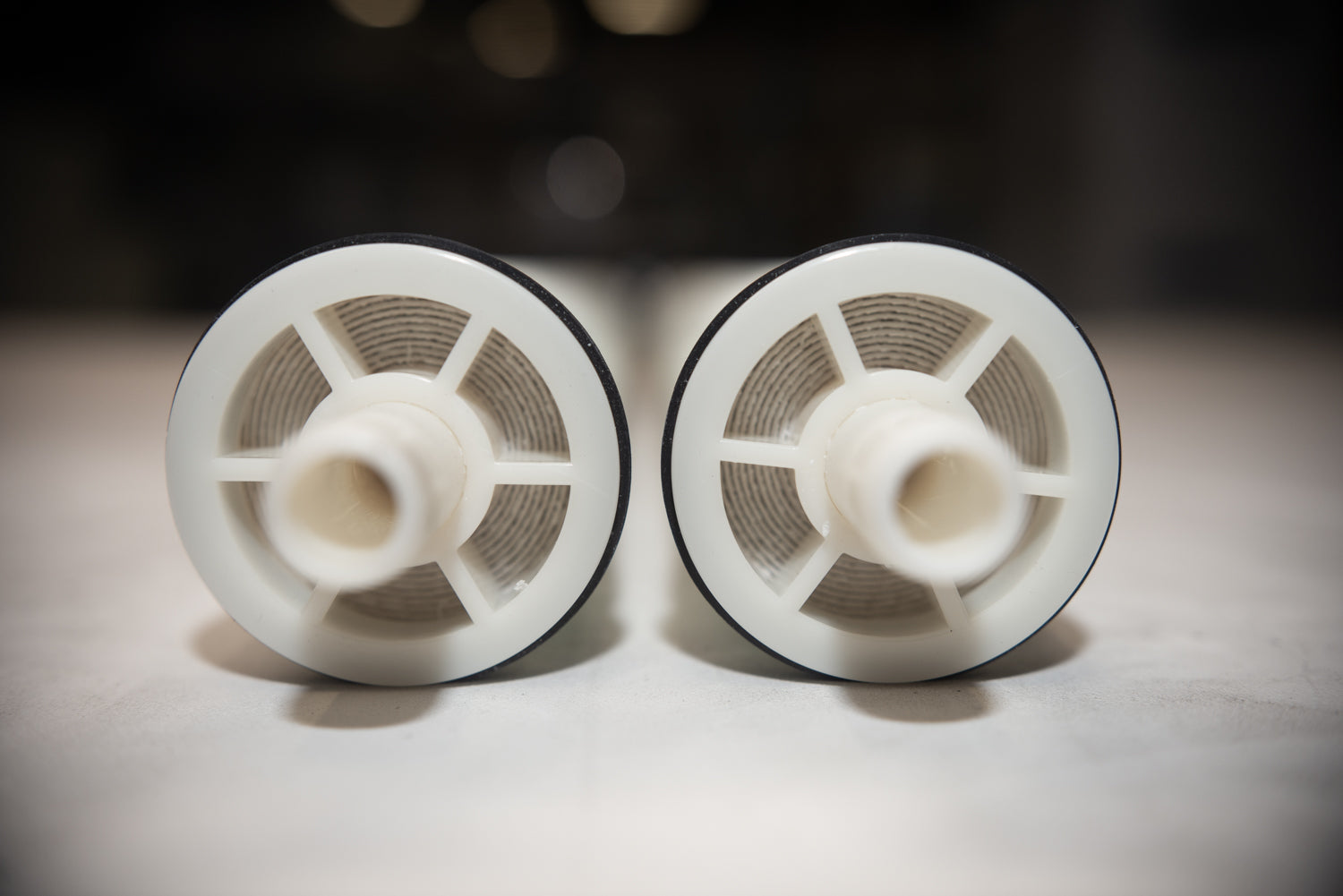

What are membranes made of?

The membranes used in water filtration systems are typically made from a synthetic material, such as a type of plastic or polymer. These materials are chosen because they are strong, durable, and resistant to the chemicals and contaminants that are commonly found in water. They are also able to withstand the high pressures that are often used in water filtration processes. The specific type of material used in a membrane can vary depending on the specific application and the type of water filtration system it is used in. Some common materials used in water filtration membranes include polysulfone, polyamide, and cellulose acetate.

The specific properties of the material used in a water filtration membrane can affect its performance and the types of impurities it is able to remove from the water. For example, a membrane made from polysulfone is strong and durable, and can withstand high temperatures and pressures. This makes it well-suited for use in reverse osmosis systems, where high pressures are used to force water molecules through the membrane. Polyamide membranes, on the other hand, are more resistant to chemical degradation, and are commonly used in nanofiltration systems. Cellulose acetate membranes are less durable than these other materials, but they are relatively inexpensive and can be used in a wide range of water filtration applications, including ultrafiltration.

Feed Water vs Permeate

In the context of water filtration, the term "permeate" refers to the water that has been treated and passed through the membrane. In other words, it is the clean, purified water that has been separated from the impurities in the water. This water is called the permeate because it has "permeated" or passed through the membrane, while the impurities have been left behind and are discarded. The term "permeate" is often used to refer to the output of a water filtration system, and it is the water that is typically collected and used for drinking or other purposes.

The term for the water that enters a water filtration system and has not yet been treated or passed through the membrane is "feed water" or "raw water". This is the water that is typically drawn from a river, lake, or other source, and it contains a variety of impurities and contaminants. The feed water is then treated by the water filtration system to remove these impurities and produce clean, purified permeate. The impurities that are removed from the feed water are typically discarded, and the purified permeate is collected for use.

In reverse osmosis, not all of the water that enters the system is able to pass through the membrane and become permeate. A significant portion of the feed water is typically rejected, meaning that it is not able to pass through the membrane and is not collected as permeate. This rejected water is often referred to as "waste water" or "brine", and it is typically discarded.

The amount of feed water that is rejected by a reverse osmosis system can vary depending on a number of factors, including the type and concentration of the impurities in the water, the pressure and flow rate of the system, and the type of membrane that is used. In general, the more impurities that are present in the water, the more feed water will be rejected by the system. For example, if the feed water has a high concentration of dissolved salts, a significant portion of it may be rejected by the system.

The high rejection rate of reverse osmosis systems can make them less efficient and cost-effective compared to other water filtration methods. This is one reason why many water filtration systems that use reverse osmosis are designed as multistage systems, where the water is treated by multiple stages of filtration. This can help to reduce the amount of feed water that is rejected and improve the overall efficiency of the system.

Membrane Filtration & Multistage Filter Systems

Reverse osmosis is a highly effective method of water filtration that can remove a wide range of impurities from water, including dissolved salts and other small molecules. However, it is not always the most suitable method for every water filtration application. In some cases, a multistage system that combines reverse osmosis with other types of filtration can provide a more effective and efficient solution.

For example, a reverse osmosis system may not be able to remove certain types of impurities, such as organic compounds or gases, from the water. In these cases, using a reverse osmosis system in combination with another type of filter, such as a granular activated carbon (GAC) cartridge, can provide a more comprehensive solution. The GAC cartridge can remove the impurities that the reverse osmosis system is unable to remove, while the reverse osmosis system can remove the other impurities from the water.

Another reason to use a multistage water filtration system is to improve the overall efficiency of the system. A reverse osmosis system can be quite inefficient, in terms of the amount of water it produces relative to the amount of feed water it consumes. By using a combination of reverse osmosis and other filtration methods, it is possible to reduce the amount of feed water that is needed to produce a given amount of purified water, which can make the system more efficient and cost-effective.

Overall, using a multistage water filtration system that includes reverse osmosis can provide a more comprehensive and efficient solution for water filtration in many cases. It allows for the removal of a wider range of impurities from the water, and can improve the overall performance and efficiency of the system.

In a multistage water filtration system, reverse osmosis is typically used as a later stage in the process, after the water has been treated by other filtration methods. This is because reverse osmosis is a more effective method of removing impurities from the water, but it is also more expensive and complex to operate than some other filtration methods. By using reverse osmosis as a later stage in the process, it is possible to remove impurities that were not removed by the earlier stages, while also reducing the overall cost and complexity of the system.

For example, in a typical multistage water filtration system, the water may first be treated by a sediment filter to remove large particles, such as sand and silt. This can help to protect the other filtration stages and improve the overall performance of the system. The water is then treated by a GAC cartridge, which can remove organic contaminants and improve the taste and odor of the water. Finally, the water is treated by a reverse osmosis system, which can remove dissolved salts and other small molecules from the water, producing high-quality permeate that is suitable for drinking or other purposes.

The specific stages and types of filtration used in a multistage water filtration system can vary depending on the specific needs and requirements of the application. Some systems may use additional stages or different types of filtration, depending on the specific impurities that need to be removed from the water. The key is to design a system that is tailored to the specific needs of the application, and that provides the most effective and efficient solution for purifying the water.

Crystal Quest offers a wide variety of multistage systems. Need help designing the perfect system for your home? Our experts are here to help:

(800) 934-0051 or help@crystalquest.com